Apple announced a major manufacturing and environmental milestone: all Apple Watch Ultra 3 and titanium Apple Watch Series 11 cases are now mass-produced using 3D printing with 100 percent recycled aerospace-grade titanium powder. This achievement, previously thought impossible at scale, represents a significant shift toward material efficiency and product sustainability.

Historically, manufacturing Apple Watch enclosures involved subtractive machining, which required large portions of raw material to be shaved off forged parts. By transitioning to the additive process of 3D printing, material is built up layer-by-layer, resulting in minimal waste.

“It wasn’t just an idea—it was an idea that wanted to become a reality,” said Kate Bergeron, Apple’s vice president of Product Design. “We had to prove, with continuous prototyping, process optimization, and a tremendous amount of data gathering, that this technology was capable of meeting the high standard of quality we demand.”

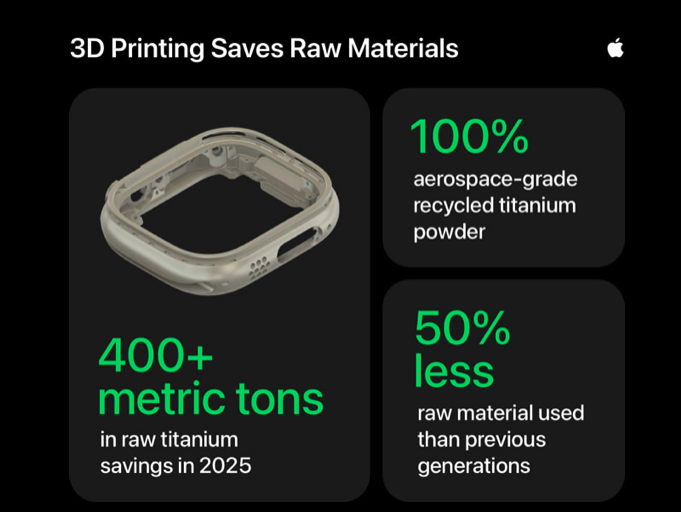

This innovative shift allows the Ultra 3 and titanium Series 11 cases to use just half the raw material compared to their previous generations.

Sarah Chandler, Apple’s vice president of Environment and Supply Chain Innovation, emphasized the environmental impact: “A 50 percent drop is a massive achievement — you’re getting two watches out of the same amount of material used for one. When you start mapping that back, the savings to the planet are tremendous.”

Apple estimates this new process will save over 400 metric tons of raw titanium this year alone.

The successful deployment of this technology is critical to Apple 2030, the company’s ambitious goal to be carbon neutral across its entire footprint by the end of the decade. All electricity used to manufacture Apple Watch already comes from renewable energy sources.

The multiyear journey required breakthroughs in materials science and manufacturing design. Dr. J Manjunathaiah, Apple’s senior director of Manufacturing Design for Apple Watch and Vision, noted the challenge: “We’ve watched this technology mature for a long time and seen its prototypes become more representative of our designs. Previously, we hadn’t been able to make cosmetic parts at scale with 3D printing.”

Engineers successfully refined the process, utilizing six lasers simultaneously to build each case, layer after layer, while ensuring the recycled titanium powder was atomized to the precise 50-micron diameter needed for successful printing. The process required meticulously controlling the powder’s oxygen content to ensure non-explosive behavior under the high heat of the lasers.

The additive manufacturing process also delivered design benefits, including the ability to print specific textures in areas previously inaccessible through forging. For cellular Apple Watch models, this allowed for improved waterproofing and better bonding between the metal case and the plastic housing the antenna.

Furthermore, this titanium 3D printing breakthrough extends beyond the Apple Watch. The company confirmed that the incredibly thin yet durable USB-C port on the new iPhone Air was made possible by 3D printing its titanium enclosure using the same recycled powder.

“We’re extraordinarily committed to systems change,” said Chandler. “Our North Star has always been to design products that are better for people and planet. When we come together to innovate without compromise across design, manufacturing, and our environmental goals, the benefits are exponentially greater than we could ever imagine.”